Trinamix Supply Network Optimization

Solution Overview

Background

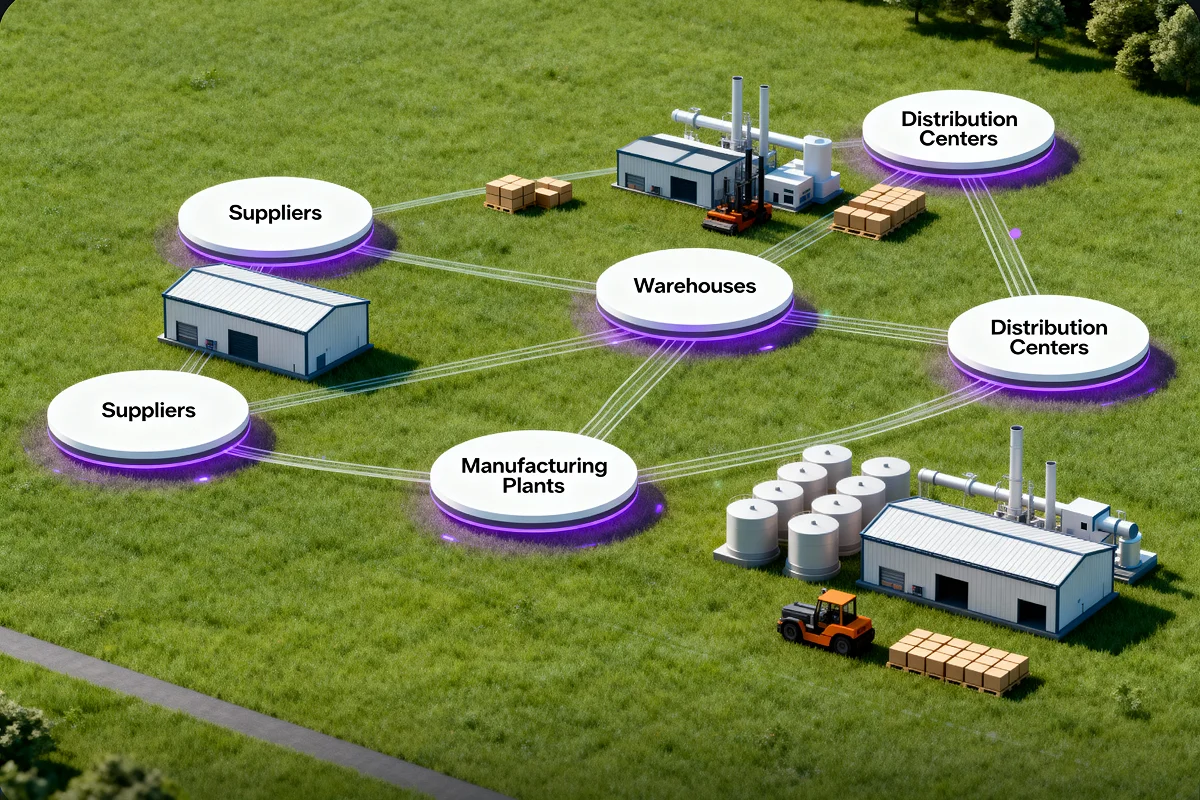

Why Trinamix Supply Network Optimization Matters

Use Cases:

Reduce Total Supply Chain Cost

Optimize sourcing decisions, production allocation, and distribution flows to minimize manufacturing, transportation, and storage costs.

Improve Network Agility

Quickly adapt to changing demand, supplier disruptions, or capacity constraints by simulating network scenarios and making informed adjustments.

Enhance Service Levels

Position facilities, suppliers, and distribution points strategically to meet customer demand efficiently and improve fulfillment performance.

Success Stories

Key Features

Supply chain simulation & digital twin

Sourcing optimization

Logistics cost optimization

Integrated scenario modeling

Key Benefits

Network-wide cost savings

Improved agility and responsiveness

Enhanced service level performance

Reduced inventory and working capital

Improvement in visibility across the supply chain

Ready to build a resilient, cost-efficient supply chain?

Other Resources

Trinamix AI Experience Lab

Building on years of success delivering AI-based solutions that drive customer transformation, Trinamix introduces the AI Experience Lab —a launchpad for enterprises to unlock AI’s potential, validate value through targeted pilots, and accelerate the journey from concept to full-scale production.

The Rise of Intelligent Enterprises: Trinamix on Building Future-Ready Businesses

What was once emerging is now essential: Artificial intelligence is driving the next era of enterprise transformation.

Frequently Asked Questions

What is Trinamix Supply Network Optimization (SNO)?

What challenges does Trinamix SNO help solve for supply chain leaders?

- High logistics and transportation costs

- Inefficient warehouse or facility placement

- Supplier disruptions and shifting demand patterns

- Limited visibility into end-to-end network performance By simulating various “what-if” scenarios, Trinamix SNO helps businesses make informed, cost-effective decisions.

How does Trinamix SNO work?

What types of scenarios can Trinamix SNO simulate?

- Supplier relocation or diversification

- Opening or closing warehouses

- Changing production capacities

- Adjusting transportation routes

- Responding to demand surges or disruptions These simulations help businesses evaluate trade-offs between cost, service level, and agility.

What are the key features of Trinamix Supply Network Optimization?

- Supply Chain Simulation & Digital Twin for end-to-end visibility

- Sourcing Optimization to balance supplier cost and distance

- Logistics Cost Optimization to reduce transport and facility costs

- Integrated Scenario Modeling for cost, risk, and performance evaluation

- AI-Driven Recommendations for smarter, faster decisions

How does Trinamix SNO integrate with existing supply chain systems?

Trinamix SNO can ingest data from any ERP, SCM, or logistics platform that captures key supply chain information — including demand data, supplier locations, transportation routes, production capacities, and cost structures. It acts as an analytical layer on top of existing systems for enhanced decision-making.

What measurable benefits can businesses expect from Trinamix SNO?

- Network-wide cost savings through optimal sourcing and logistics planning

- Network-wide cost savings through optimal sourcing and logistics planning

- Improved agility to adapt to market or supply disruptions

- Enhanced service levels with smarter facility and route positioning

- Reduced working capital by minimizing excess inventory

- Improved end-to-end visibility for better strategic control