Solution Overview

Background

Success stories

A Leading Canadian Utilities Conglomerate Collaborates with Trinamix for the Implementation of Oracle Fusion Analytics Warehouse (FAW) Integrated with Oracle ERP Cloud

Trinamix enhanced end-to-end visibility of inventory from

PO placement through end-of-life decommissioning.

Australia’s Leading Manufacturer of Windows and Doors Selects Trinamix for Oracle End-to-End ERP-SCM-CX Cloud Implementation

Trinamix helped Block create a reverse auction capability

that it uses to regularly solicit new bids from its suppliers.

A Global Technology Corporation Seeks the Expertise of Trinamix for End-to-End Oracle ERP-SCM-CX Cloud Implementation with A Multi-Country Rollout

Key Features

Hold management

Custom interface for quality inspections

Hold reasons tracking

Real-time reporting and analytics

Automated notifications & workflows

Partial disposition support

Audit Trail & compliance

Hold tagging

Key Benefits

Seamless integration

Integrate with Oracle Quality Inspection and Inventory Cloud, leveraging existing systems to create a unified and automated quality control process.

Enhanced quality control

Provide real-time control over material holds, ensuring that any problematic products are quarantined and inspected before further use or shipment.

Operational efficiency

Streamline quality control processes by automating workflows and notifications, reducing downtime, and ensuring faster resolution of issues.

Transparency & accountability

Ensure transparency by capturing and tracking the root cause of product issues, with detailed records of responsible parties and actions taken.

Regulatory compliance & traceability

Help companies comply with industry regulations for food safety and traceability by ensuring that necessary quality checks are documented and transparent.

Other resources

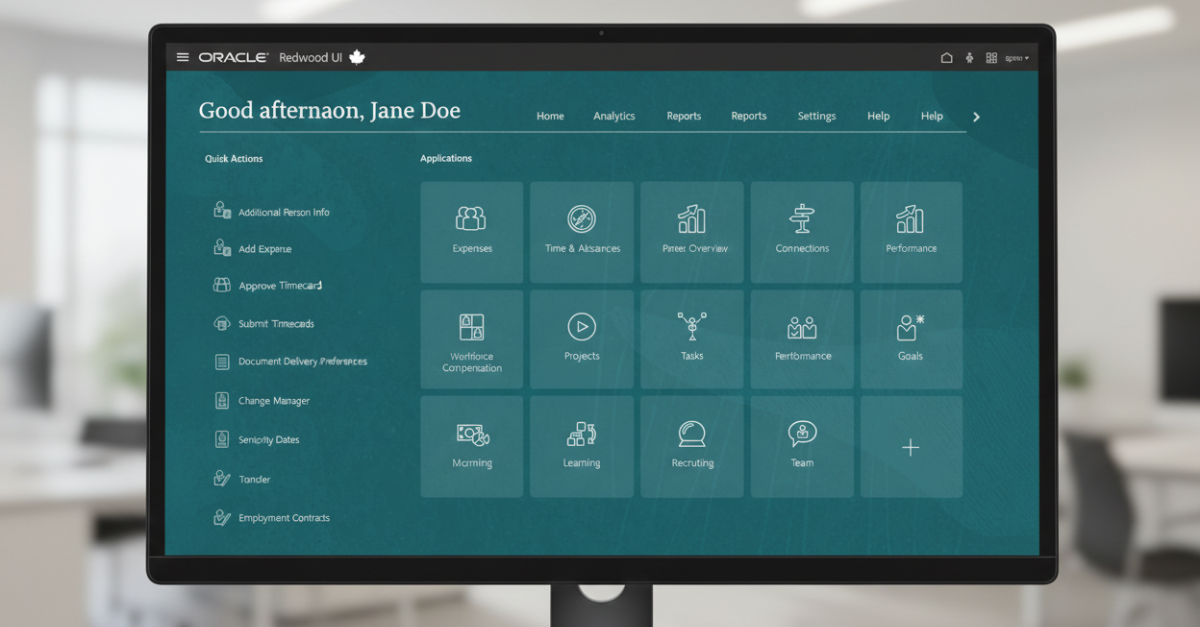

Redwood UI – How It’s Changing and How It Differs from the Previous UI

User experience is no longer just about navigation and screen layouts—it’s about

Understanding Generative AI: What it is and how it works

In today’s fast-evolving digital landscape, Generative AI (GenAI) is no longer just

Inside Oracle AI World 2025: Trinamix Highlights and Takeaways from a Game-Changing Week in AI

Oracle AI World 2025 marked an exciting milestone in Trinamix’s journey to

Extending Oracle Smart Operations: The Emerging Patterns of Cloud MES Adoption

Extending Oracle Smart Operations to Meet Industry-Specific Needs As we continue our

Frequently asked questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua…Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua…