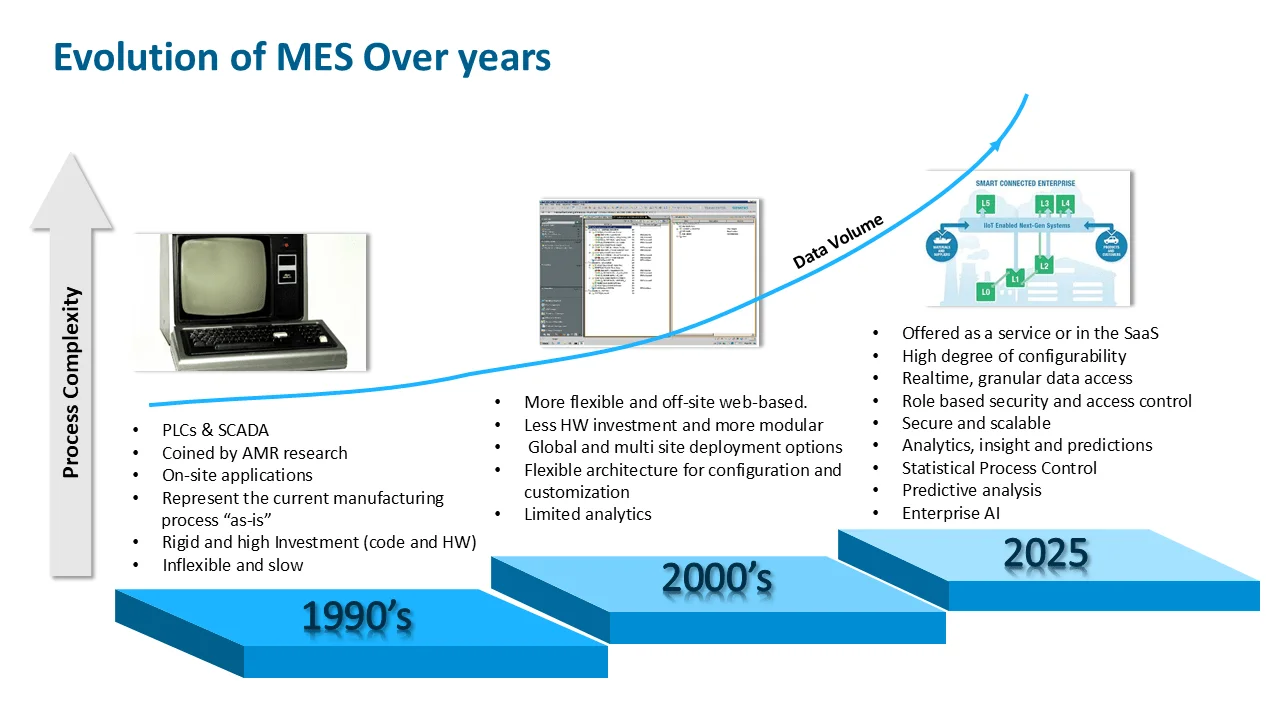

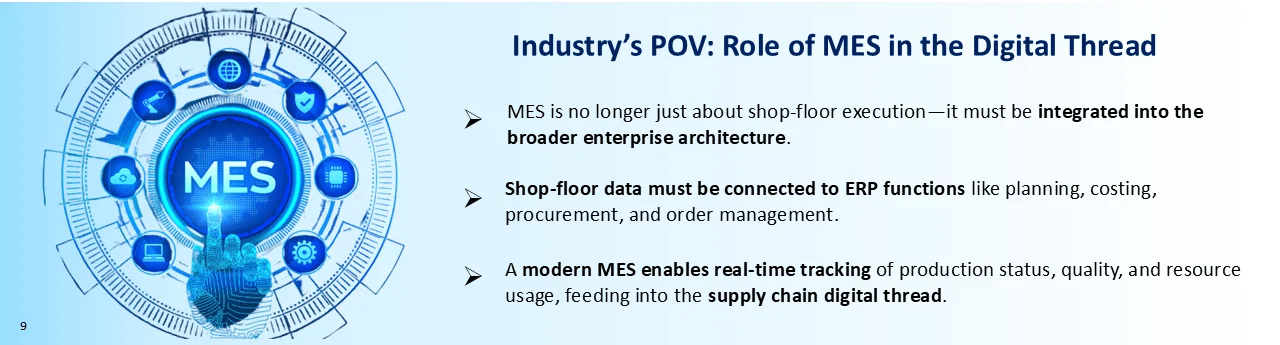

Manufacturing is at the heart of modern industry, but it has long faced challenges related to disconnected shop-floor data, rigid legacy systems, and a lack of real-time insights. Manufacturing Execution Systems (MES) have played a crucial role in bridging this gap, providing manufacturers with a way to track job movements, material planning, scheduling, and quality management — all while evolving significantly over the years.

Key Challenges Driving the Need for Cloud MES

The manufacturing industry today faces challenges of outdated MES systems — solutions that continue to remain isolated from other enterprise systems driving business processes. Data in these systems have limited integration capabilities. These systems have outdated user interfaces and lack modern analytics. Last but not least, they are extremely limited in their adoption of AI and predictive analytics.

At the same time, modern manufacturing’s push toward smart and efficient principles, the need for increased operational efficiencies, the use of predictive and preventive analysis on manufacturing data, and the aspiration to adopt the latest technologies like digital twins and AI are accelerating the need for digital transformation around MES.

Is Oracle Cloud Smart Operations the Answer to Modern MES in the Cloud?

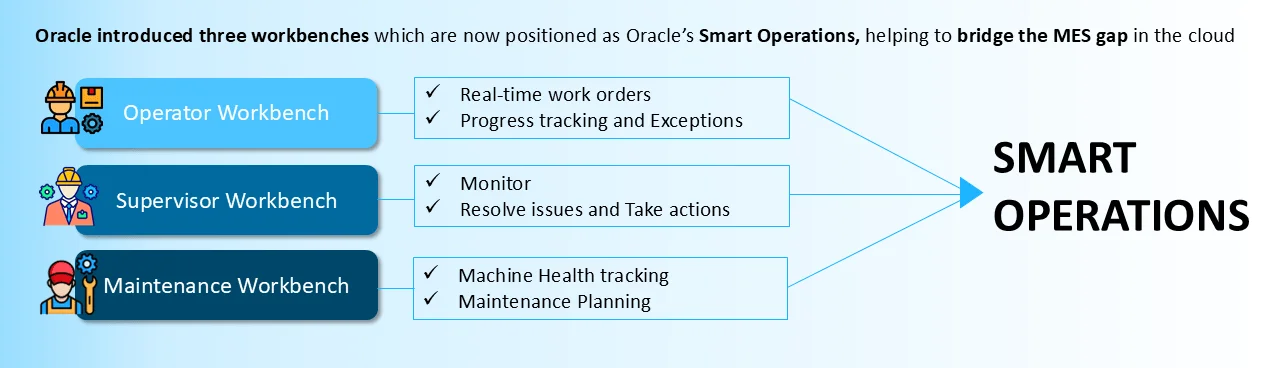

Oracle’s MES Capabilities: Bridging the Digital Gap

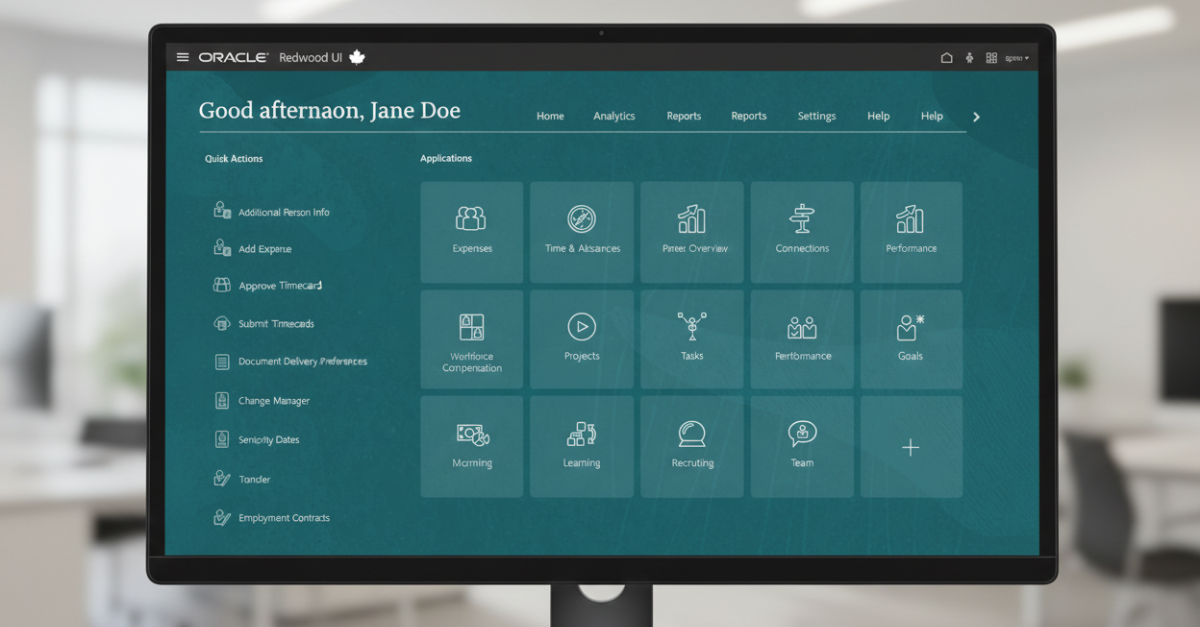

Oracle has recently introduced the Smart Operations solution as an additional capability within its cloud manufacturing release, addressing the need for a modern MES solution that the manufacturing industry has been waiting for. Oracle Smart Operations brings real-time or near real-time connectivity and visibility to manufacturing operations from the shop floor. Oracle Smart Operations introduces a new way of managing shop-floor execution by providing a suite of integrated workbenches that allow shop-floor operators and supervisors to track and report production and maintenance operation progress in the cloud.

This enables the establishment of a digital twin of the “connected supply chain,” including manufacturing operations. It also breaks the silo of isolated manufacturing data and connects manufacturing with the rest of the enterprise business processes. This establishes a framework to execute advanced analytics and AI models for better understanding and analysis of end-to-end business processes. The connected manufacturing data model helps enable advanced process analysis around preventive and predictive maintenance of production lines, production yield, quality prediction, product recall analysis, proactive supply chain planning, and build optimization, among others.

Follow our series of blogs in the coming days as we dive deep into further analysis of Oracle Cloud Smart Operations’ readiness to address MES needs across multiple industries.

Authors

- Prantik Chakraborty, VP, Sales & Delivery – Trinamix

- Abhishek Mishra, Senior Content Manager – Trinamix