Trinamix Service Parts Planning

Solution Overview

Trinamix Service Parts Planning (SPP) is comprehensive solution for managing Service Parts in ERP Cloud/Legacy ERP

It is a complimentary extension to Cloud Planning Suite including Demand, Supply & Replenishment Planning and enhances /introduces some of the key SPP capabilities as given below.

Supercession modelling in forward logistics flow

- Complex Supercession Modelling and Visualization

- Consider Supercession Relationship in Allocation Logic

- Complex chaining/NPI in Spare Part Forecasting Process based on Supercession relationship

Reverse material flow

- Incorporate defective supplies in Allocation Logic

- Plan Repair activity for their repairs and defective repaired to usable inventory by honoring Repair LT, Yield etc

Integration

- Out of the box Integration with any of Cloud Demand Planning, Supply Planning & Replenishment Planning application

- It will also have feature to mass load input data sets like item, Item Relationship, Supply/demand etc through FBDI or can be collected programmatically from any ERP Source inc Fusion ERP

Background

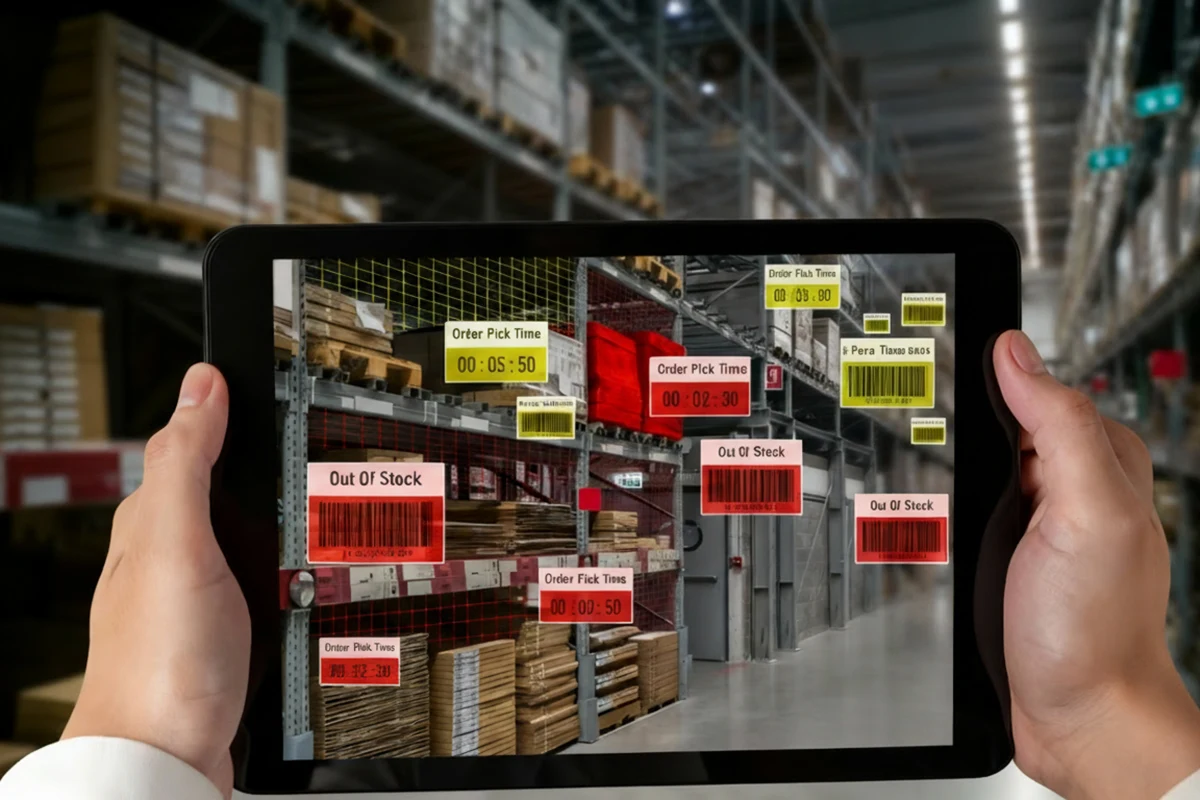

Service Parts Planning challenges are usually faced by companies in Industrial Manufacturing, High Tech, Healthcare and Oil & Gas industries. Some of the challenges include:

- Stringent industry requirements

- Critical equipment needs to be available immediately and they likely have purchased Service Contracts with same-day fix commitments/ specific ETA for fix

- Large portion of service parts is business to business (B2B) rather than business to consumer (B2C)

- Demand is not typically influenced by sales or promotions and Failure Events are Random

- Right spare parts are in the right place to fix things that break. Building a supply chain network that allows for near immediate, sometimes global availability of key parts

- High cost of “downtime” are incurred in most of the scenarios

Success stories

Key Features

- Consideration of supersession relationship in allocation

- Consideration of defective supplies in allocation

- Consideration of usable supply in repair process

- Item relationship network diagram

- Review of demand & supply based on top item

- Matrix report by top item to review allocation calculation

- Detailed pegging report by top item to review allocation calculation

- Generation of repair supplies

Other resources

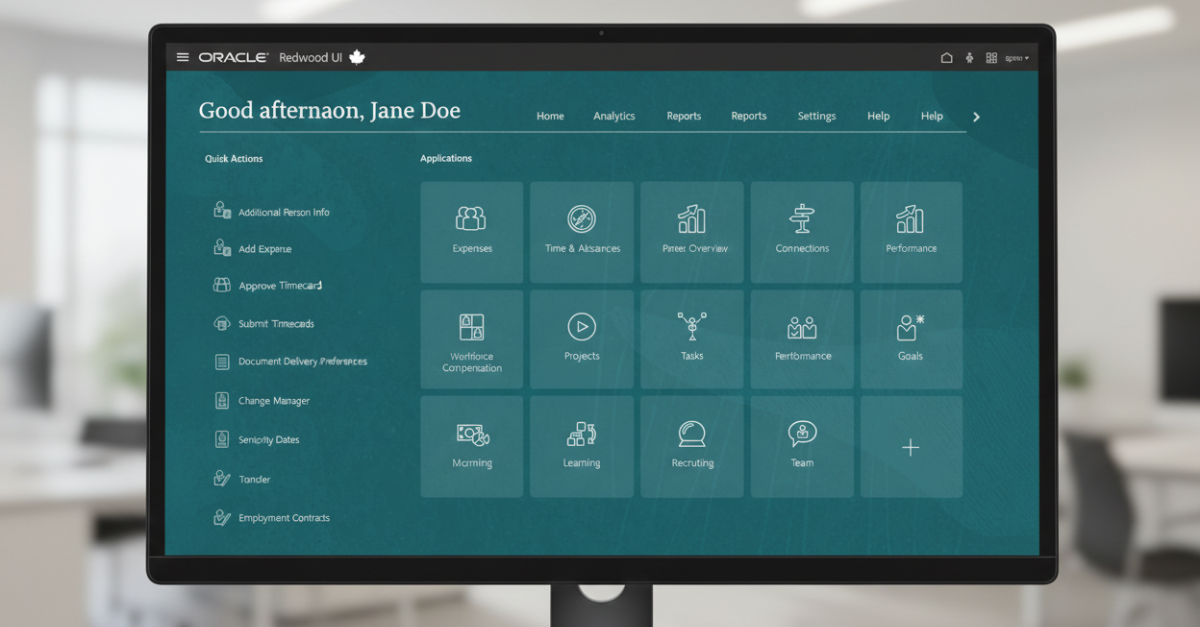

Redwood UI – How It’s Changing and How It Differs from the Previous UI

User experience is no longer just about navigation and screen layouts—it’s about

Understanding Generative AI: What it is and how it works

In today’s fast-evolving digital landscape, Generative AI (GenAI) is no longer just

Inside Oracle AI World 2025: Trinamix Highlights and Takeaways from a Game-Changing Week in AI

Oracle AI World 2025 marked an exciting milestone in Trinamix’s journey to

Extending Oracle Smart Operations: The Emerging Patterns of Cloud MES Adoption

Extending Oracle Smart Operations to Meet Industry-Specific Needs As we continue our

Frequently asked questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua…Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua…