Extending Oracle Smart Operations to Meet Industry-Specific Needs

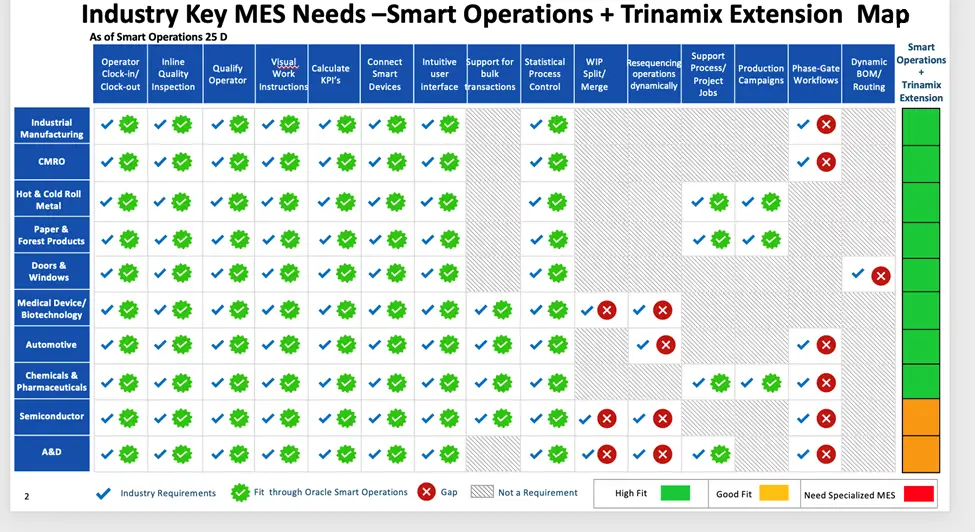

- Statistical Process Control (SPC): A core MES requirement across Semiconductors, Pharmaceuticals, and High-Precision Manufacturing. While SPC is planned for future Oracle releases, Trinamix delivers analytics-based SPC dashboards and visual insights that monitor process variation and quality metrics in real time.

- Campaign Scheduling and Trim Optimization: Crucial for Paper & Pulp, Metals, and Alloys downstream industries, where yield and material utilization drive profitability. Trinamix has built cloud-native scheduling and optimization extensions that enable production campaigns and trim management directly within Oracle Smart Operations.

- Build-Together Scheduling: Essential for Doors & Windows and custom assembly industries, where multiple sub-assemblies must progress in sync. Trinamix provides build-together orchestration extensions ensuring coordinated work-order execution across production lines.

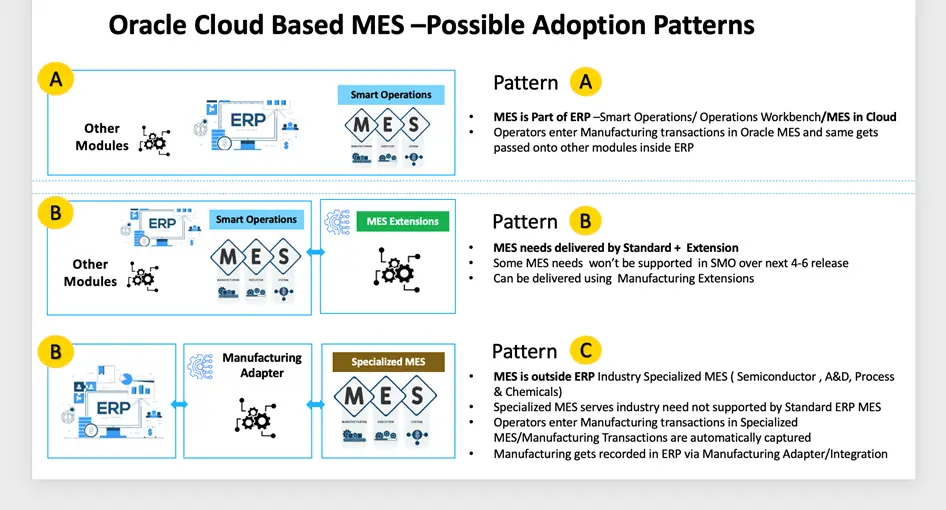

How Smart Operations / MES Cloud Adoption Will Evolve

Pattern A – MES Fully in the Cloud (Out-of-the-Box Smart Operations)

Manufacturers adopt Oracle Smart Operations as delivered, using standard workbenches and operator UIs to record production transactions directly in the cloud. This model is best suited for organizations with moderate complexity and a strong preference for a simplified, unified ERP–MES architecture.

Pattern B – Cloud MES with Extensions

Industries with specialized MES requirements leverage Trinamix extensions to complement Smart Operations until Oracle delivers these functions natively. This hybrid model blends Oracle’s standard cloud capabilities with targeted industry add-ons, ensuring continuity and upgrade compatibility without disruption.

Looking Ahead

The future of MES in the Oracle Cloud will not follow a single, uniform path — it will evolve across three distinct patterns, reflecting the diverse needs of modern manufacturing landscapes.

👉 Meet Trinamix at Oracle AI World — Booth #3003 to discover how we can help you extend Oracle Smart Operations and accelerate your MES transformation journey.

Authors

- Prantik Chakraborty, VP, Sales & Delivery – Trinamix