Solution Overview

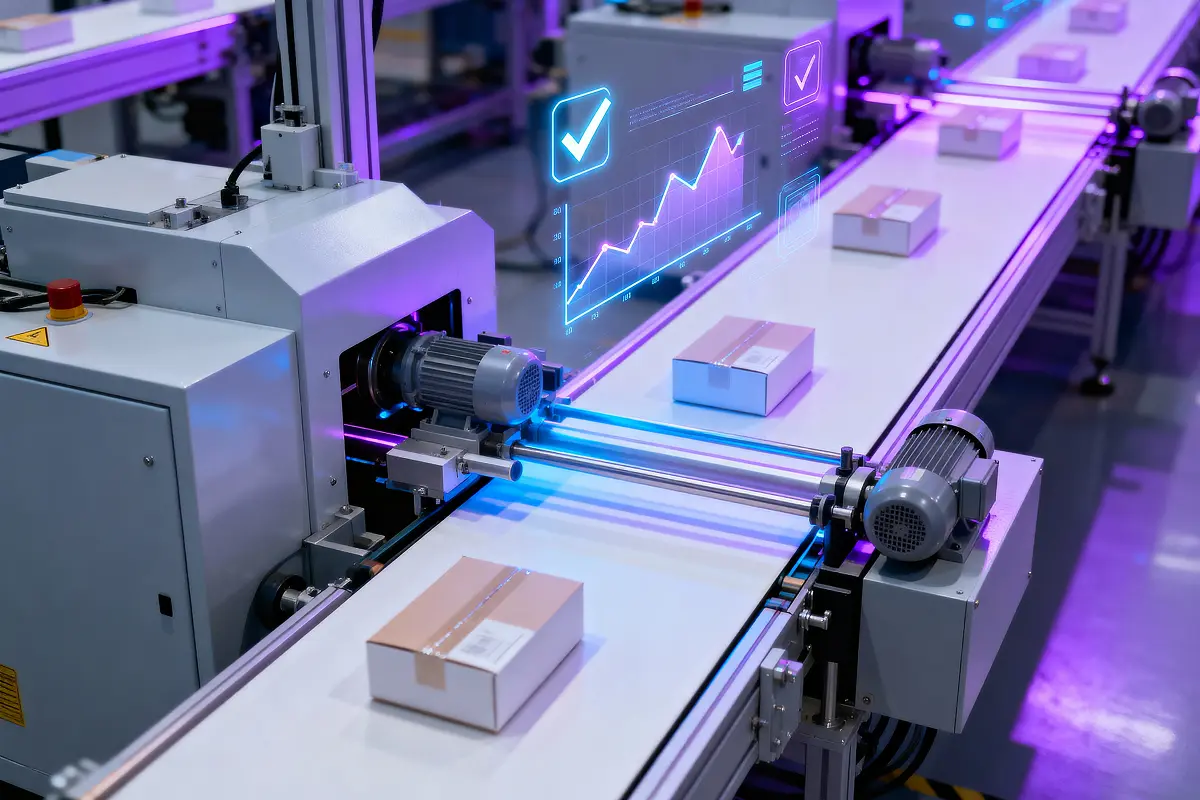

Trinamix AI-MFG is an AI-powered solution for predictive yield optimization, purpose-built for today’s complex manufacturing operations. It continuously ingests, analyses, and correlates massive datasets from across the shop floor—ranging from test equipment and SCADA systems to machine configurations and failure logs—to uncover hidden yield-impacting variables and suggest intelligent interventions.

By generating AI-powered insights and real-time alerts, Trinamix AI-MFG empowers manufacturers to reduce scrap, enhance throughput, and improve equipment utilization. It not only predicts product quality but also forecasts machine downtimes, recommends optimal configuration schedules, and proactively prevents production disruptions.

Background

Why Trinamix AI-MFG Matters

Trinamix AI-MFG flawlessly integrates with MES, SCADA, and other enterprise systems, enabling manufacturers to unify IT and OT data, simulate optimal process settings, and implement real-time corrections that significantly improve yield and operational efficiency. With its modular, scalable architecture, the platform empowers domain experts and operations teams to shift from reactive firefighting to proactive, precision manufacturing.

Use Cases:

Analyse multi-variable process and equipment data → Predict yield-impacting anomalies and potential machine breakdowns → Recommend optimized equipment settings and maintenance actions → Enhance yield and reduce operational risk.

Ensure Consistent

Yield

Variations in machine and process parameters directly affect product output—predictive insights ensure quality across production cycles.

Minimize Downtime & Waste

Equipment failures or misconfigurations can lead to scrap and delays—early detection and AI-driven forecasts minimize these risks.

Optimize Machine Utilization

The platform analyses machine usage patterns, schedules, and health metrics to recommend when and how to best configure and maintain equipment.

Enable Informed Decision-Making

It blends human and machine intelligence—giving your team the power to act decisively and confidently, backed by data.

Success Stories

Key Features

Statistical process analysis

Machine learning-based yield prediction

Anomaly detection

Optimization engine

Integrated EDA visualization

Key Benefits

Predictable yield improvement

Enhanced decision

support

Reduced process variability & downtime

Faster AI-driven root cause identification

Improved machine configuration & maintenance scheduling

Other Resources

Trinamix Documantra

Over the last ten years, value chains have grown in length and complexity as companies expanded globally in pursuit of margin improvements. Even though they operate in a world where disruptions are commonplace, intricate production networks have historically been built for cost, efficiency, and proximity to markets rather than for resilience or transparency.

Trinamix Casual IQ

Trinamix Causal IQ is an AI-powered sales forecasting solution designed to enhance demand predictions by correlating a wide array of external influences.

Trinamix DDMRP for Resilient Planning

Trinamix Documantra is an integrated solution that seamlessly converts complete documents into actionable insights and empowers businesses to make informed decisions and drive growth.

Ready to unlock predictable, data-driven manufacturing?