In our continued exploration of Oracle Smart Operations as a modern answer to Manufacturing Execution System (MES) needs in the cloud, we extended our research across nine major industry segments — including Industrial Manufacturing, Automotive, Metals, Paper & Forest Products, Medical Devices, Chemicals & Pharma, Complex Maintenance, Repair and Overhaul, Semiconductor, Aerospace & Défense, and Doors and Windows Manufacturing.

Each of these sectors has unique production models, compliance frameworks, and shop-floor realities. Yet, our cross-industry analysis revealed a remarkably consistent set of MES priorities — spanning from visual work instructions, operator qualification, and inline quality inspections to dynamic resequencing, statistical process control, operator and supervisor visualization and more.

Top MES Priorities That Transcend Industries

Despite their operational diversity, manufacturers are converging around a core set of MES capabilities that define “smart” execution in the modern enterprise:

- Visual and contextual work instructions that guide the operator in real time.

- Seamless operator interaction and qualification tracking for regulated environments.

- Integrated quality capture and KPI visibility directly on the shop floor.

- Connectivity to smart devices and sensors for live production insight.

- Dynamic and flexible execution — handling campaign production, WIP split/merge, resequencing, and phase-gate workflows.

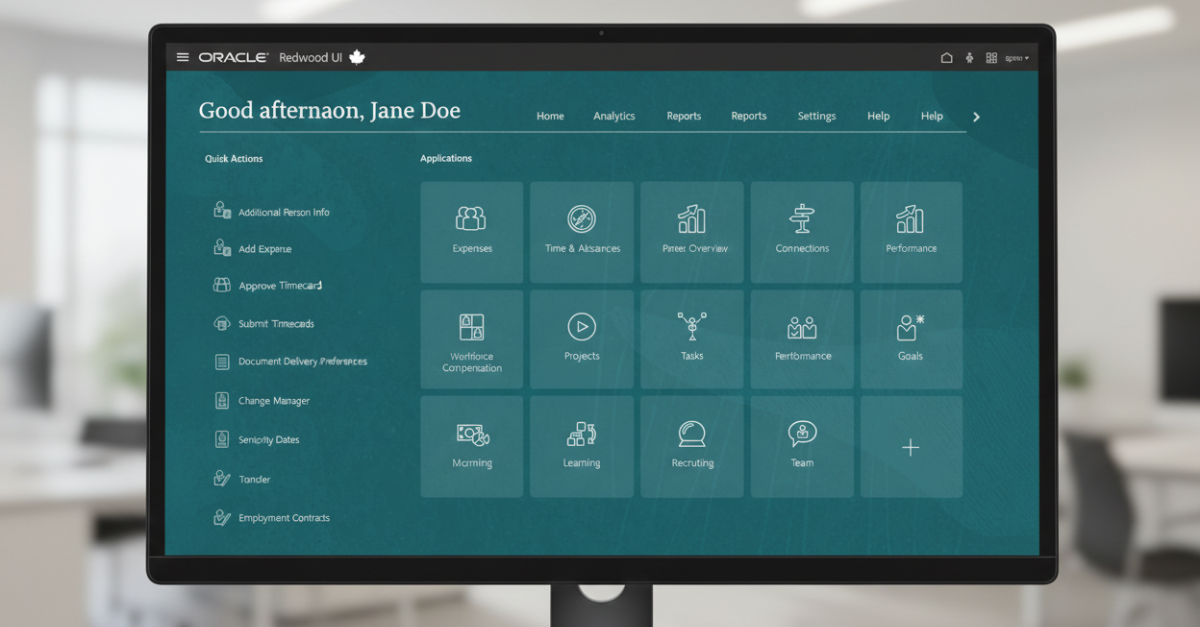

- Ease of use and intuitive UI supporting both process and discrete manufacturing styles.

Oracle Smart Operations: Strong Alignment Across Industries

When mapped against these MES imperatives, Oracle Smart Operations 25C demonstrates broad functional alignment across almost all industry segments. A list of capabilities, such as:

- Intuitive User Interface

- Ease of Onboarding New Lines and Factories

- Visual Work Instructions

- Operator Qualification

- Smart Device Connectivity

- Inline Quality and KPI Tracking

- Support for Bulk Transactions

- Dynamic BOM/Routing Adjustments

Collectively, these capabilities deliver a “high to good fit” across the majority of industries analysed. For highly specialized sectors (e.g., semiconductor fabrication or process manufacturing), Oracle Smart Operations complements — rather than replaces — domain-specific MES tools, serving as an extensible digital operations foundation within the Oracle Cloud ecosystem.

Key Takeaway

Our analysis confirms that Oracle Smart Operations is not a niche solution but a cross-industry, MES-class platform — purpose-built for the cloud era, adaptable to multiple manufacturing modes, and natively integrated with Oracle’s Supply Chain and Manufacturing suite. It effectively closes the historical gap between ERP and shop-floor execution, positioning enterprises for end-to-end operational intelligence.

This solution is quickly evolving to address multiple industry MES needs. In the last of our current series, we will dive deep into which industries have a high fit for adopting Smart Operations and MES in the cloud, and for which industries Trinamix is adding additional capabilities to meet specific industry needs.

Authors

- Prantik Chakraborty, VP, Sales & Delivery – Trinamix