Challenges

About the company

- Industry: Food & Beverage Manufacturing

- Market Standing: Leading beverage manufacturer with a strong retail and distribution network across Europe

- Product Portfolio: Wide range of carbonated and non-carbonated drinks

- Geographic Presence: Operates multiple manufacturing plants and distribution centres across Europe

- Operational Focus: Fast-paced, high-volume production with seasonal demand spikes

Approach

Project Objectives

- Optimized Production Sequencing: Improve production flow by minimizing changeovers and maximizing resource utilization

- Demand-Adaptive Scheduling: Dynamically align production plans with real-time customer demand signals

- Operational Efficiency Gains: Reduce production downtime, changeover costs, and manual scheduling efforts

- Enhanced Delivery Performance: Improve on-time order fulfilment to boost customer satisfaction

- Data-Driven Decision Making: Empower planners with scenario simulation tools and AI-driven schedule recommendations

Project Highlights

- 20% Reduction in Changeover Time: Achieved through intelligent production grouping

- 15% Improvement in On-Time Delivery: By aligning production with dynamic demand patterns

- Automated Scheduling: Reduced manual planning efforts by over 30%

- AI-Powered Scenario Planning: Enabled planners to run simulations and quickly adjust schedules

- Enhanced Planner Productivity: Provided intuitive dashboards and schedule visualization tools

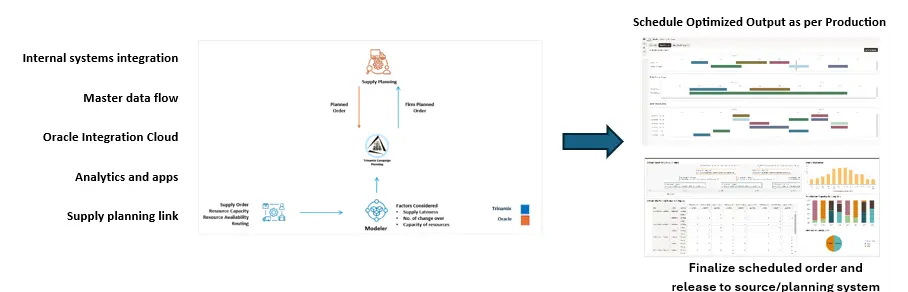

Solution Architecture

How Trinamix Campaign Planning Works

Here’s how it works, in simple terms:

- Understands Capacity and Availability: It checks which production lines, work centres, and equipment are available, factoring in maintenance schedules and workforce availability

- Groups Similar Products: For example, if you’re producing multiple flavors of beverages, it automatically groups similar batches (like all citrus-based drinks) to reduce changeover and cleaning time between runs

- Adapts to Last-Minute Order Changes: If a large distributor suddenly places an urgent order for a specific product, the system can quickly reshuffle the schedule to meet the deadline—without throwing the whole production plan off track

- Simulates Multiple Planning Scenarios: Suppose there’s a choice between completing smaller retail orders first or fulfilling a large bulk shipment to a supermarket chain. The system lets planners run both scenarios, showing trade-offs in delivery time, utilization, and costs

- Provides Real-Time Dashboard Insights: Planners get a visual snapshot of key production KPIs—like how much machine time is being utilized, how many changeovers are scheduled, and which customer orders are at risk of delay

- Seamlessly Integrates with Oracle Cloud: It connects directly with Oracle Supply Planning and Manufacturing Cloud, so the production plan flows straight from planning into execution without manual data entry

Example Scenario:

Imagine you’re a production planner at a beverage plant with five bottling lines.

- Before Trinamix Campaign Planning: You’re juggling orders for sparkling water, fruit juices, and energy drinks—all coming from different customers with different deadlines. Your schedule is built manually in Excel. Changeovers between product types take hours. A sudden rush order throws your whole schedule into chaos, and customer orders get delayed

- After Trinamix Campaign Planning: The system automatically groups similar drink types together—scheduling all citrus drinks before switching to berry flavours, for example—reducing cleaning and changeover time. When a last-minute order comes in, the system instantly simulates how to fit it in without impacting other deliveries. You now meet deadlines more consistently, reduce overtime costs, and keep production lines running at higher utilization

Proven Results – Step-by-Step Progress with Tangible Outcomes

10% – Planning Workshops

Kick-off with discovery workshops to understand current production complexities, resource constraints, and scheduling challenges.

20% – Data Collection and Configuration

Collaborate with business users to collect data on resources, production orders, changeover rules, and planning horizons. Configure the scheduling engine to match business needs.

30% – Scenario Simulation and KPI Validation

Run multiple scheduling simulations to assess trade-offs between delivery performance, changeover costs, and resource utilization. Validate KPIs like on-time delivery and changeover reduction.

50% – Production Scheduling Rollout

Deploy the optimized scheduling model across production facilities. Enable planners with real-time dashboards, scenario tools, and integration with Oracle Cloud for continuous execution and monitoring.

Results

- 20% Decrease in Changeover Hours: Across all production lines

- 15% Improvement in Order Fill Rates: Leading to stronger customer satisfaction

- 30% Reduction in Manual Planning Time: Freeing up planners for value-added activities

- Increased Equipment Utilization: By over 18%

- Scenario-Driven Planning Decisions: Ability to model and compare multiple scheduling outcomes within minutes

- End-to-End Oracle Integration: Ensuring real-time data flow between planning and execution systems

Want more information?