Trinamix Campaign Planning

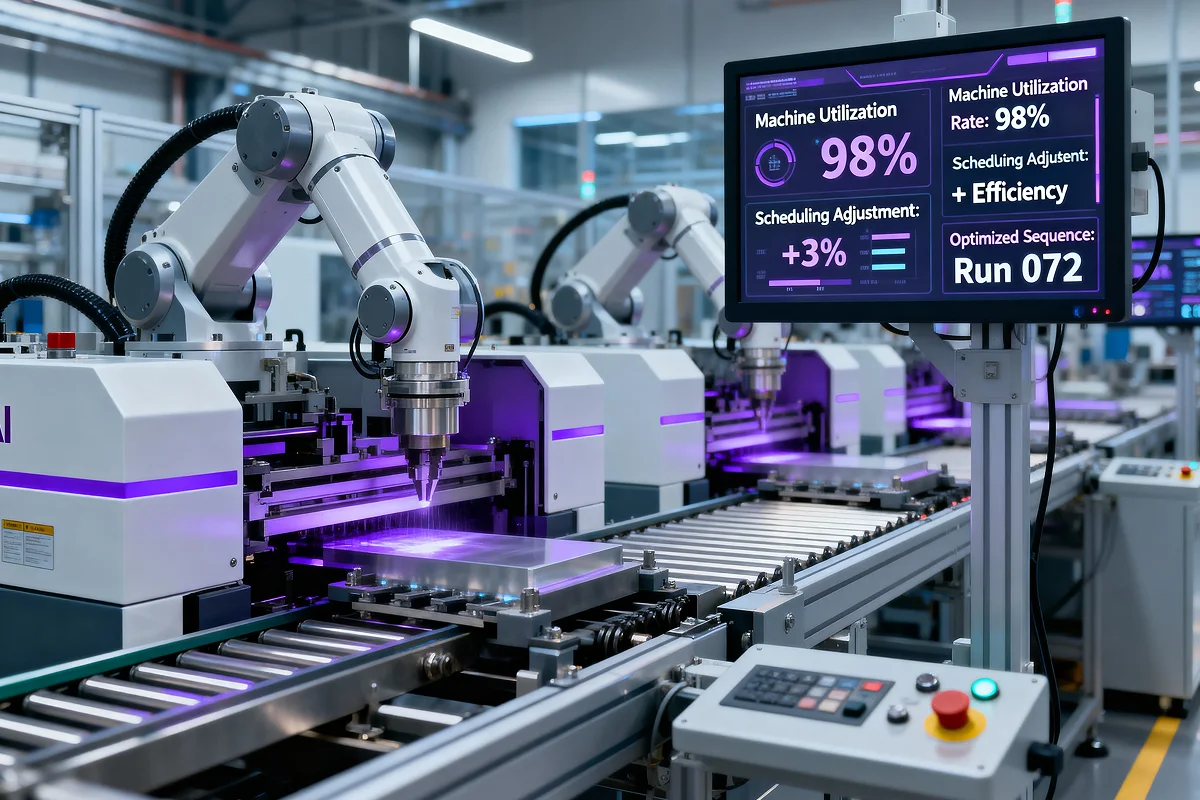

Revolutionizing how industries optimize their production schedules

Solution Overview

Trinamix Campaign Planning is a cutting-edge solution tailored to streamline production schedules in fast-paced manufacturing environments. It integrates seamlessly with Oracle Demand Planning, Master Data, and Available Resource to optimize campaigns. The optimizer’s output is fed into the Supply Planning Cloud, which passes detailed plans to production scheduling.

Trinamix Campaign Planning groups similar production batches into campaigns and aligns them with optimal time slots, reducing changeovers and ensuring seamless operations. Built on the modular architecture, Trinamix Campaign Planning features components for scheduling, interactive simulation, execution, and analytics. It also has machine learning capabilities to simulate multiple production scenarios and evaluate trade-offs such as cost, efficiency, and delivery timelines. Additionally, the solution integrates effortlessly with existing ERP systems, providing scalability for businesses of all sizes.

Trinamix Campaign Planning delivers measurable improvements by leveraging AI-driven insights, dynamic slot allocation, and campaign grouping. This solution transforms traditional scheduling methods into a smarter, automated process, bridging the gap between operational efficiency and business goals for pharmaceuticals, packaging, and other fast-paced manufacturing sectors.

Background

As the manufacturing industry rapidly evolves, optimized production schedules are key to staying competitive. Manufacturers face constant pressure to meet tight delivery deadlines, manage intricate workflows, and minimize operational costs. Challenges such as frequent equipment changeovers, underutilized machinery, and limited visibility into planning trade-offs often hinder efficiency and profitability.

Trinamix Campaign Planning addresses these challenges, leveraging cutting-edge AI capabilities to streamline production planning, align operations with customer expectations, and drive sustainable growth.

Top 3 core objectives of Trinamix Campaign Planning

Reduce Demand Lateness

By aligning production schedules with customer deadlines, the solution ensures that manufacturing campaigns are planned to meet delivery commitments.

Minimize Changeovers

The solution intelligently groups similar production batches, reducing the need for frequent equipment cleaning and setup adjustments.

Maximize Equipment Utilization

Advanced scheduling and sequencing algorithms ensure machines operate at peak capacity, reducing idle time and optimizing resource usage.

Success Stories

A leading rental and real estate company in the U.S.—ranked second nationally in its sector—embarked on an enterprise-wide Oracle Financials Cloud transformation. As part of this modernization, the organization faced significant hurdles in extracting critical information from thousands of legacy contracts

A leading beverage manufacturer in Europe—known for its wide portfolio of popular drinks—faced growing complexity in managing production schedules and meeting dynamic market demand.

A global consumer electronics brand, recognized for its innovative gaming peripherals, sought to enhance its promotional strategy through a data-driven, AI-enabled approach. Despite running numerous campaigns across direct-to-consumer, retail, and e-commerce channels,

Key Features

- Intelligent campaign prioritization

- Scenario simulation and optimization

- Real-time adjustments

- Analytics and reporting

Key Benefits

Operational efficiency

- Reduction in waste

- Improved productivity

Cost saving

- Lower changeover costs

- Higher ROI

Enhanced customer satisfaction

- On-time deliveries

- Flexible order fulfillment

Scalability and adaptability

- Future-proof planning

- AI-Driven insights

Sustainability

- Eco-friendly operations

- Efficient resource utilization

Other Resources

The Rise of Intelligent Enterprises: Trinamix on Building Future-Ready Businesses

What was once emerging is now essential: Artificial intelligence is driving the next era of enterprise transformation.

Frequently Asked Questions

What is Trinamix Campaign Planning?

Trinamix Campaign Planning is an AI-driven production scheduling solution that helps manufacturers streamline operations, reduce changeovers, and maximize equipment utilization. It intelligently groups similar production batches into optimized campaigns, ensuring efficient, on-time, and cost-effective manufacturing.

What challenges does Trinamix Campaign Planning solve for manufacturers?

It addresses key manufacturing pain points such as:

- Frequent equipment changeovers

- Underutilized machinery

- Limited visibility into planning trade-offs

- Difficulty meeting tight delivery deadlines By automating and optimizing scheduling, it helps manufacturers achieve higher efficiency and profitability

How does Trinamix Campaign Planning work?

The solution integrates seamlessly with Oracle Demand Planning, Master Data, and Available Resource modules to generate optimized production schedules. It feeds optimized plans into the Oracle Supply Planning Cloud, which then drives detailed production scheduling and execution.

What industries benefit most from Trinamix Campaign Planning?

It’s ideal for pharmaceutical, packaging, and fast-paced manufacturing sectors where batch production, strict quality standards, and frequent changeovers are common. The solution’s modular design also makes it adaptable across other manufacturing domains.

What are the main objectives of Trinamix Campaign Planning?

The solution is designed to achieve three primary goals:

- Reduce Demand Lateness – Meet customer delivery deadlines more reliably.

- Minimize Changeovers – Group similar batches to reduce equipment downtime.

- Maximize Equipment Utilization – Optimize machine schedules for continuous production.

What are the key features of Trinamix Campaign Planning?

- Intelligent Campaign Prioritization

- Demand-Driven Scheduling

- Campaign Grouping

- Dynamic Slot Allocation

- Scenario Simulation and Optimization

- Real-Time Adjustments

- Analytics and Reporting

How does AI enhance Trinamix Campaign Planning?

AI and machine learning models simulate multiple production scenarios and evaluate trade-offs between cost, efficiency, and delivery timelines. This allows planners to make data-driven decisions, minimize risks, and continuously improve operational performance

Can Trinamix Campaign Planning integrate with existing ERP systems?

Yes. The solution is built with a modular and scalable architecture that integrates effortlessly with existing ERP platforms, including Oracle Cloud applications, ensuring smooth data flow and minimal implementation effort.

What measurable benefits can manufacturers expect?

- Increased operational efficiency

- Reduced production waste and changeover time

- Improved resource utilization

- Cost savings and higher ROI

- On-time delivery and enhanced customer satisfaction

- Flexible order fulfillment and scalable operations

How does Trinamix Campaign Planning support sustainability goals?

By optimizing equipment utilization and reducing waste, the solution promotes eco-friendly operations and efficient resource usage, aligning production efficiency with sustainability initiatives.