Trinamix Trim Optimization

Solution Overview

Background

Efficient material utilization is a top priority in industries like steel, paper, and textiles. However, traditional cutting and trimming processes often result in significant material waste, increased costs, and slower production cycles. As these industries push for higher efficiency and sustainability, leveraging advanced technologies is crucial.

Why Trinamix Trim Optimization Matters

True Optimization

Automatically creates cutting patterns and plans for robust optimization.

Optimized Order Combining

Efficiently combines orders to maximize material use and reduce waste.

User-Friendly Interface

Easy-to-learn with an innovative, visually appealing graphical user interface.

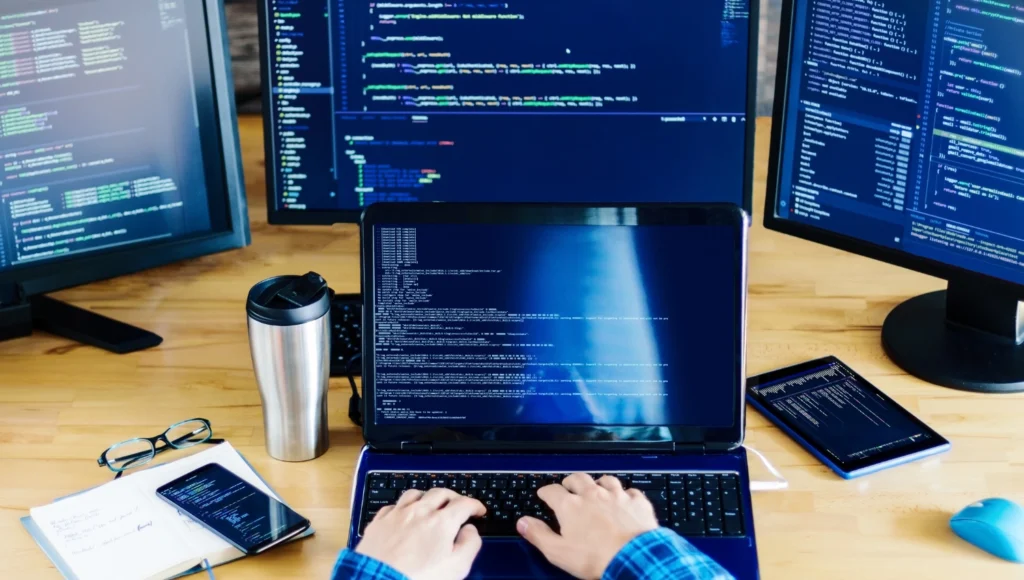

Real-Time Data Integration

Syncs with real-time inventory and order management systems, enabling on-the-fly optimization based on current data.

Success Stories

Key Features

Automated cut pattern generation

Real-time integration

- Inventory: Synchronizes with real-time inventory data to suggest trims that utilize available materials and minimize excess.

- Order Management Systems: Fetches order details, resource availability, and production schedules.

Customizable constraints

Allows users to set production-specific constraints such as size limitations, quality standards, and waste thresholds.

Changeover optimization

- Reduces the frequency of knife changeovers.

- Streamlines operations, saving time and reducing wear on machinery.

Performance analytics dashboard

Machine learning adaptation

Multi-industry applicability

- Metal Industry: Optimizes sheet and coil cutting processes, reducing waste.

- Paper Industry: Efficiently slices rolls to meet precise dimensions, minimizing scrap.

- Textile Industry: Maximizes fabric usage by optimizing pattern layouts.

Key Benefits

Cost

Savings

Improved Production Speed

Increased

Profitability

Enhanced Product Quality

Sustainability

Scalability and Flexibility

Ready to optimize every cut?

Other resources

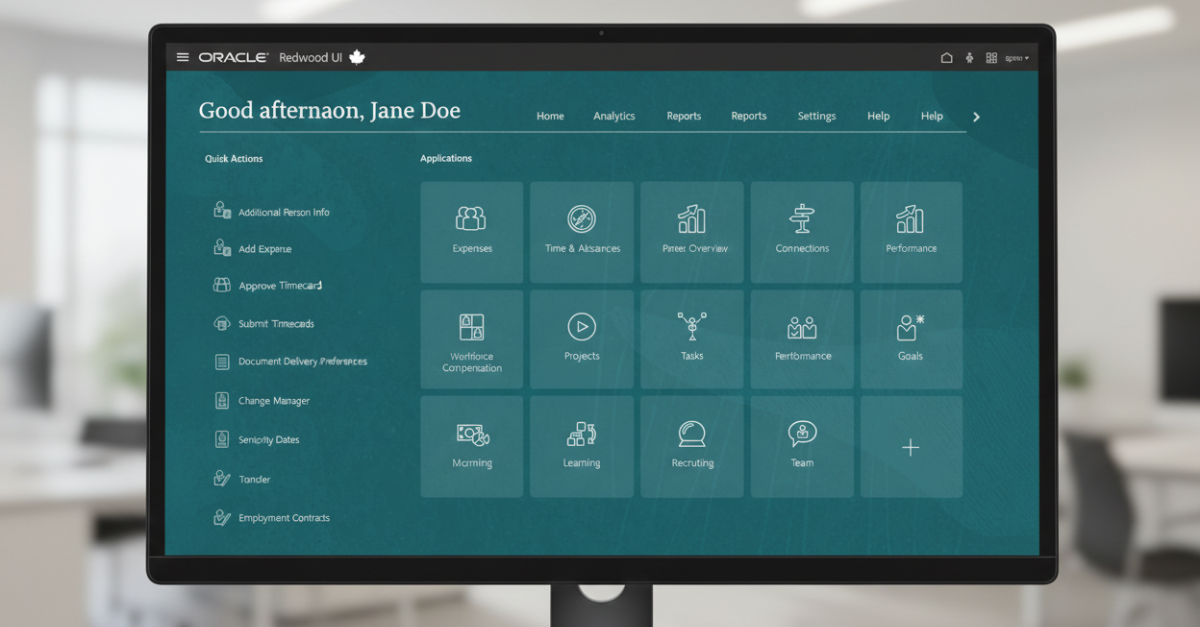

Redwood UI – How It’s Changing and How It Differs from the Previous UI

User experience is no longer just about navigation and screen layouts—it’s about

Understanding Generative AI: What it is and how it works

In today’s fast-evolving digital landscape, Generative AI (GenAI) is no longer just

Inside Oracle AI World 2025: Trinamix Highlights and Takeaways from a Game-Changing Week in AI

Oracle AI World 2025 marked an exciting milestone in Trinamix’s journey to

Extending Oracle Smart Operations: The Emerging Patterns of Cloud MES Adoption

Extending Oracle Smart Operations to Meet Industry-Specific Needs As we continue our

Frequently asked questions

Lorem ipsum dolor sit amet, consectetur adipiscing elit

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua…Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua…